Adopts world-famous brands of electrical and pneumatic components, low failure rate, reliable performance, long service life.

Material contact parts are made of stainless steel, easy to disassemble and assemble, easy to clean and meet the requirements of GMP.

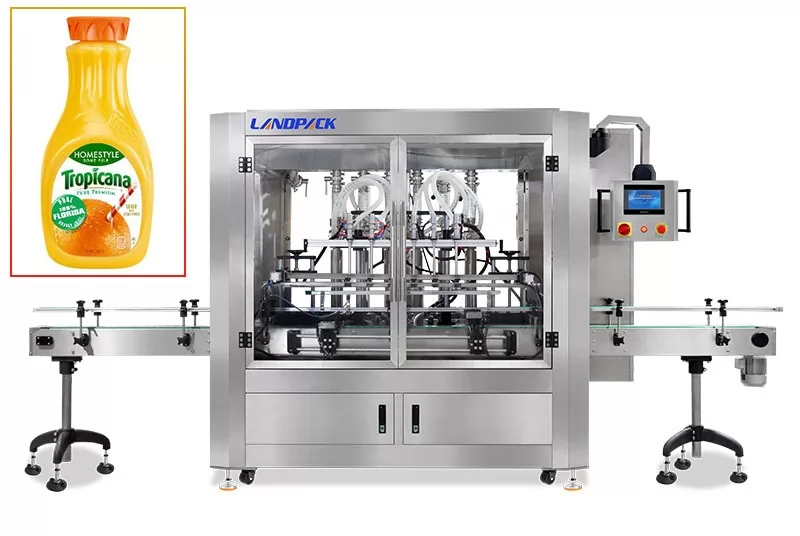

Easy to adjust filling volume and filling speed, operated and displayed by touch screen, beautiful appearance.

With no bottle no filling function, liquid level automatic control feeding.

Piston Seals with Tetrafluorine Technology improve the wear resistance of the piston seals (service life is 12 months or more) and have a good applicability to materials.

No need to change parts, you can quickly adjust the various specifications of the shape of the bottle.

The filling head is equipped with a special leak-proof device. No wire drawing or drip leakage.