We specialize in all kinds of packaging machines. Most customers have printing needs on products. Therefore, our coding machines are also varied. We commonly use ribbon coding, Ink roller coding, and steel stamping coding, laser coding, thermal transfer coding and ink jet coding.

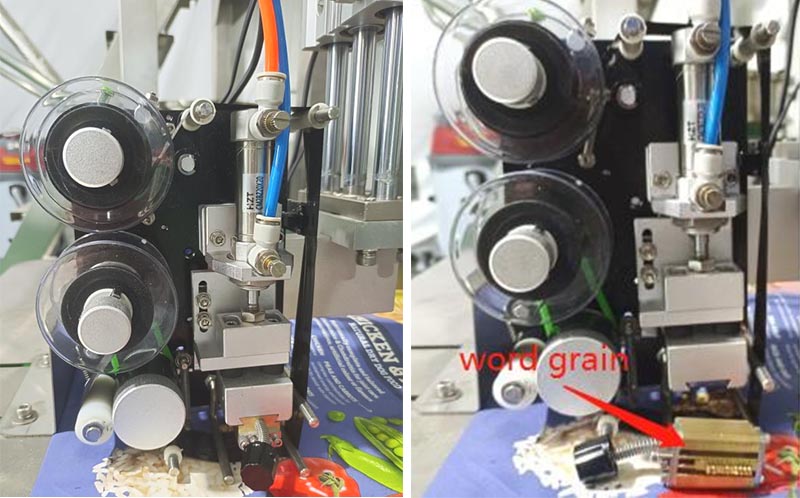

1. Ribbon coding machine

Ribbon coding machine is one of coding machine, which uses thermal printing tape instead of ink to print, adopts special movable type loading and unloading structure, and can code on any flexible packaging material. The printing is clear and not easy to wipe off; it is hygienic and clean, and there is no worry of ink pollution. It is an economical and hygienic coding method. Ribbon coding machine is intermittent coding, we generally use ribbon coding on Vertical Packing Machines, Doypack Packing Machine and Labeling Machine.

Finished product:

2.Ink roller coding machine

As the name implies, the ink roller coding machine uses ink for coding, using advanced solid ink rollers, which has the excellent performance of instant printing and instant drying, and is not easy to erase, especially suitable for non-absorbent materials such as plastic film, metal foil and paper package. Ink roller coding machine is continuous coding, we generally use the Ink roller coding machine to code on the Flow Packing Machine.

Finished product:

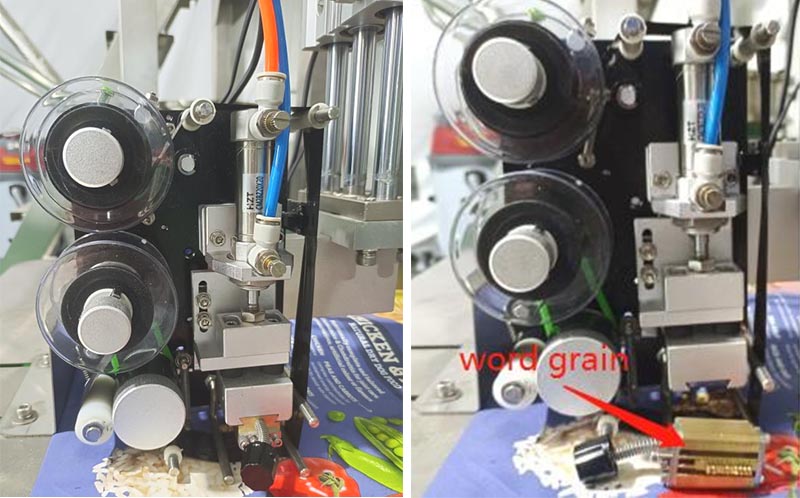

3. Steel stamping coding machine

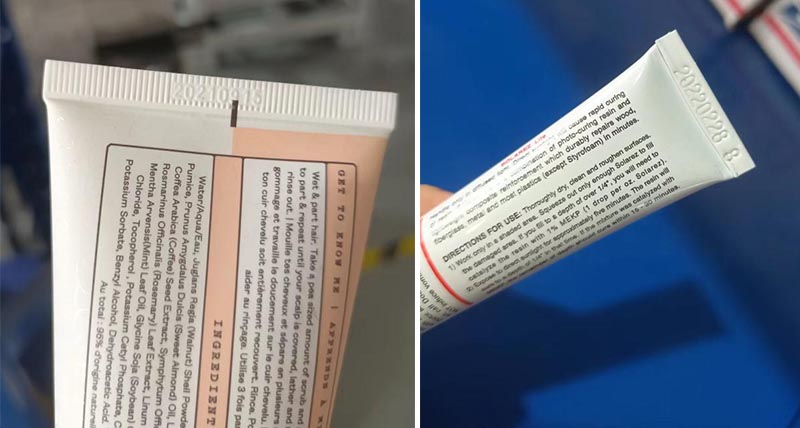

The steel stamping coding machine is the most material-saving coding machine. Unlike the above ribbon coding machine and ink roller coding machine, the ribbon and ink roller need to be replaced. The working principle of the steel printing code is to use pressure to print the word grains, for products with thicker materials or relatively printed products. We use steel stamping coding machine on the end-sealing machine to stamp the dates required by customers on various plastic and aluminum tubes.

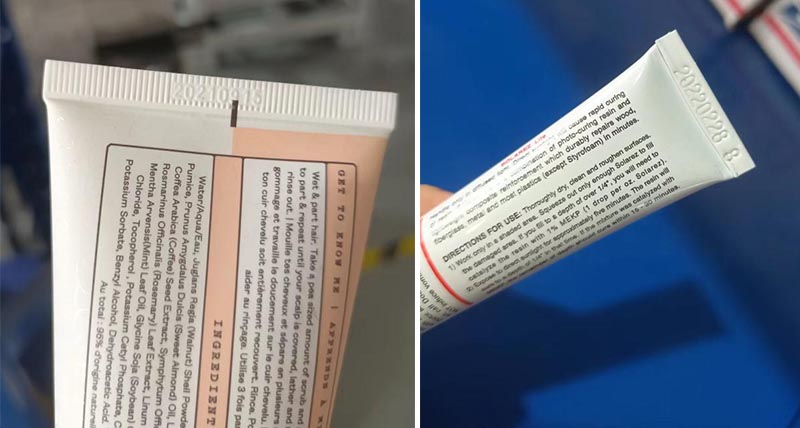

Finished product:

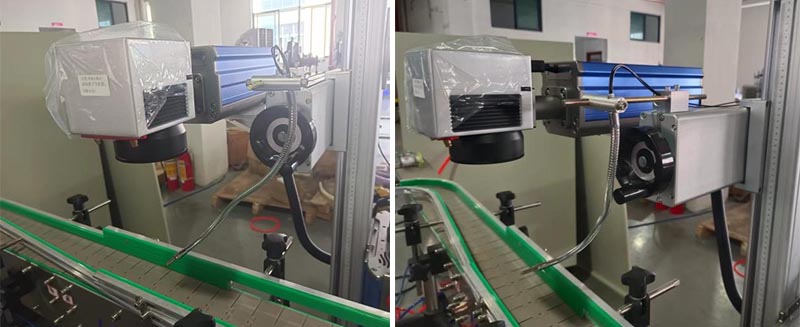

4. Laser coder

Laser coder is also a low-energy-consuming printer that does not need to replace any materials. Its working principle is to use laser beams to corrode permanent signs on the surface of various materials, such as trademarks, two-dimensional codes, text, barcode etc. It is a very advanced coding equipment with good quality, fast speed, low energy consumption and good stability. We usually use a laser coder on the filling machine, and use a laser to mark the bottom of the can with the product name and date required by the customer.

Finished product:

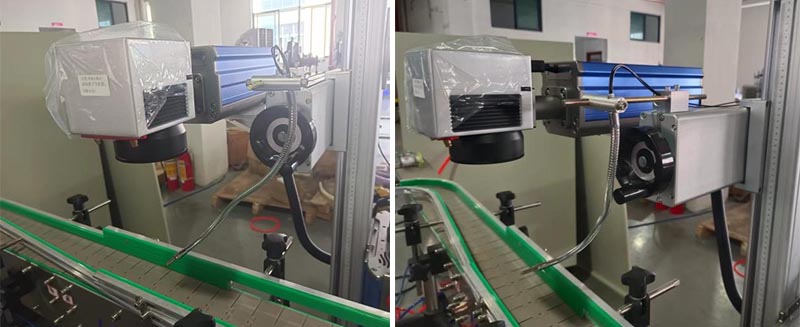

5. Thermal transfer coding machine

The thermal transfer coding machine uses advanced thermal transfer coding technology. Its ribbon consumption is very small. It can print continuously or intermittently, and can also directly code on packaging materials. The industry has a very good economic advantage. Its high-resolution printhead can print text, graphics, batch numbers, real-time dates and barcodes, etc. It has the characteristics of fast printing speed, stable and clear printed patterns.

Finished product: