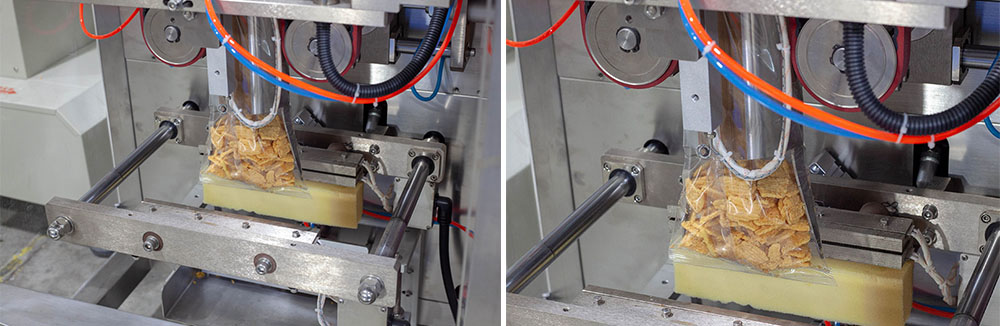

The upward granule bundling machine frequently cuts materials when it is working, which will cause the pack mouth to be not firmly shut, which will influence the appearance and become side-effects. So what is the justification for why the upward granule bundling machine frequently cuts materials?

The justifications for why the upward granule bundling machine frequently clasps materials:

1. The particular of the set bundling sack is excessively short, and the filled material is excessively full, bringing about material bracing;

2. The material filling and fixing of the upward granule bundling machine are not very much coordinated, the material filling is quick, and the fixing is slow;

3. Quick fixing and slow filling of materials;

4. The dumping gadget isn't sufficiently tight, which makes the material tumble to the seal when the material is fixed by the repacking machine;

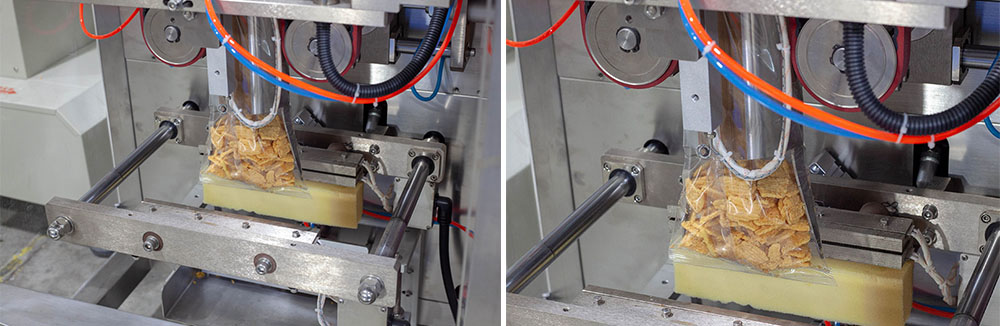

5. Vertical granule bundling machine bundling curl electrostatic adsorption materials;

6. In the event that it is furnished with nitrogen, the expansion pressure is excessively huge, which will make the material be lifted and clasped on the flat seal.

The answer for the regular bracing of the upward granule bundling machine:

1. Change sack size or lessen material;

2. Change the taking care of season of the estimating cup estimating gadget or electronic scale to match the even fixing; or straightforwardly change the flat fixing time;

3. Really look at the snugness of the gadget, and supplant it in the event that it is viewed as not tight;

4. Wipe out the electricity produced via friction of the bundling loop, or add a particle wind gadget;

5. Appropriately change the expansion pressure;