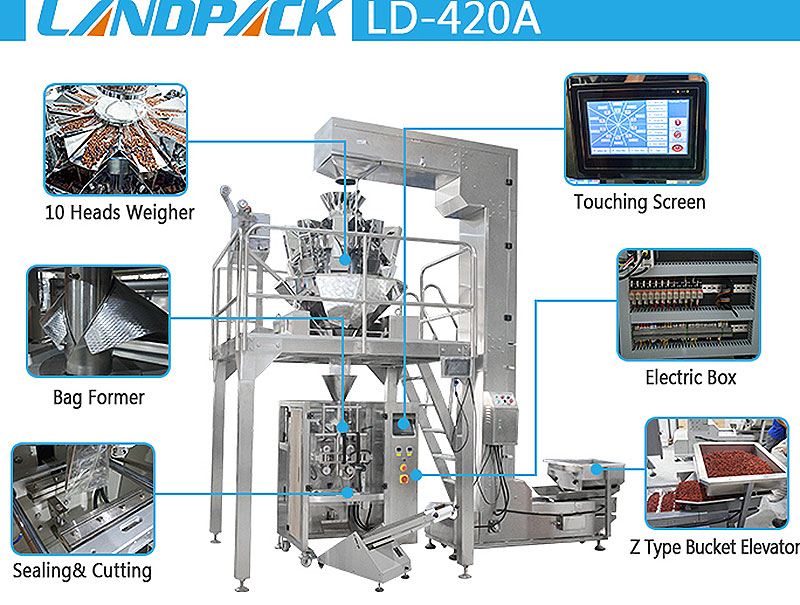

The weighing packaging machine is specially designed for quantitative packaging equipment for granular materials. Adopt advanced stainless steel weighing sensor, special weighing control terminal, programmable controller technology, and single barrel net weight measurement to realize all actions in the process of quantitative packaging of materials. , The packaging scale has the characteristics of high precision, fast speed, strong environmental adaptability, and good system reliability.

The specific performance advantages of the weighing packaging machine:

1. The structural parts of the packaging machine except the motor are made of 304 stainless steel, which is corrosion-resistant and durable;

2. The parts in contact with the material can be easily disassembled and washed;

3. Using high-precision instruments, the weighing is accurate and stable;

4. The appearance is novel and beautiful, equipped with a touch screen, which can switch between Chinese and English interface operations;

5. Reliable performance, simple operation, stable operation, low noise, convenient maintenance, and corrosion resistance;

6. The full Chinese LCD display clearly displays the working status and operation instructions, which is simple and intuitive;

7. With weighing setting, storage, modification, electronic weighing, high precision, and other functions.

Operation points of quantitative weighing packaging machine:

When the packaging machine enters the automatic running state, the weighing control system opens the feeding door to start feeding. When the material weight reaches the set value of fast feeding, stop fast feeding and keep slow feeding; when the weight of material reaches the set value, close the feeding door to complete the dynamic weighing process; at this time, the system detects whether the bag clamping device is in the predetermined position state. When the packaging bag is clamped, the system sends a control signal to open the discharge door of the weighing hopper, and the material enters the packaging bag. After the material is unloaded, the discharge door of the weighing hopper is automatically closed; after unloading, the bag clamping device is released, and the packaging bag automatically falls; after the packaging bag falls, the bag is sewn and transported to the next station. This cycle goes back and forth automatically.

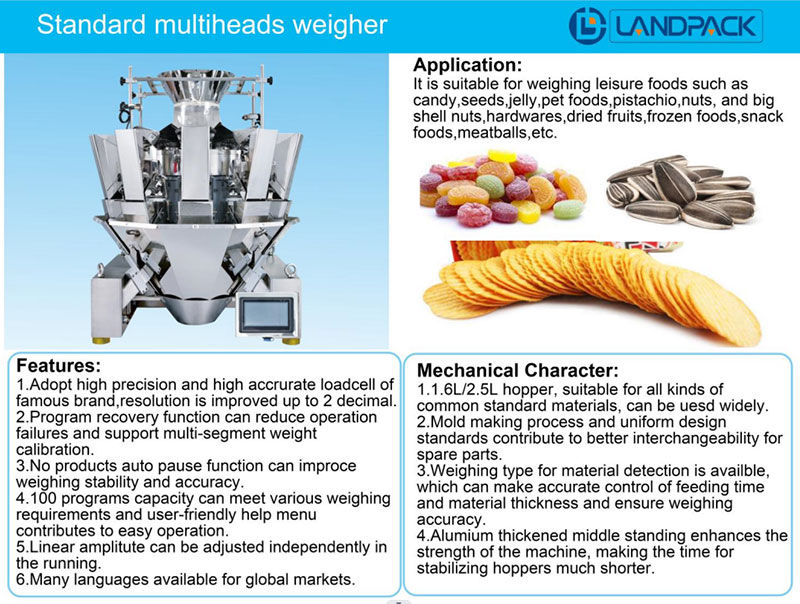

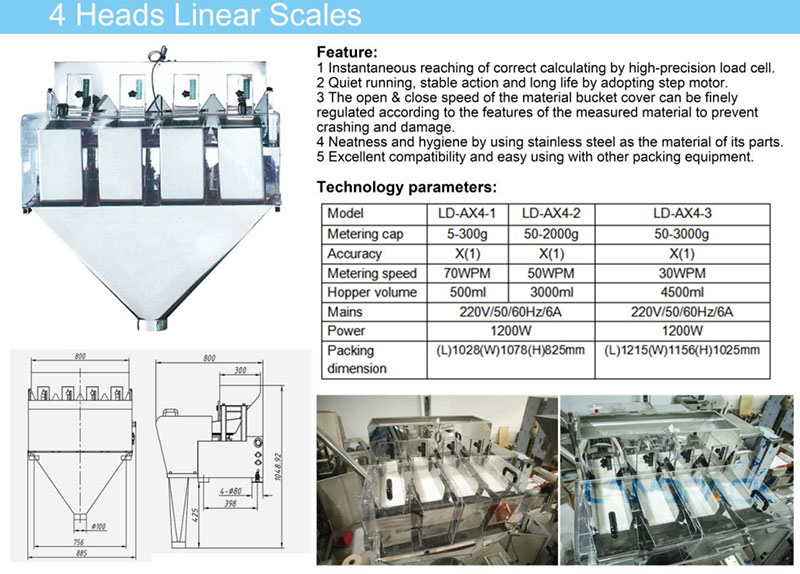

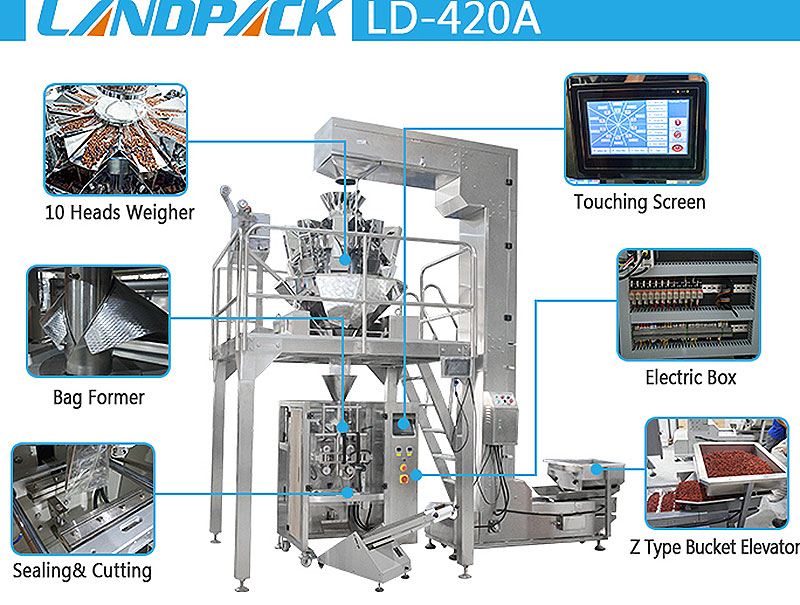

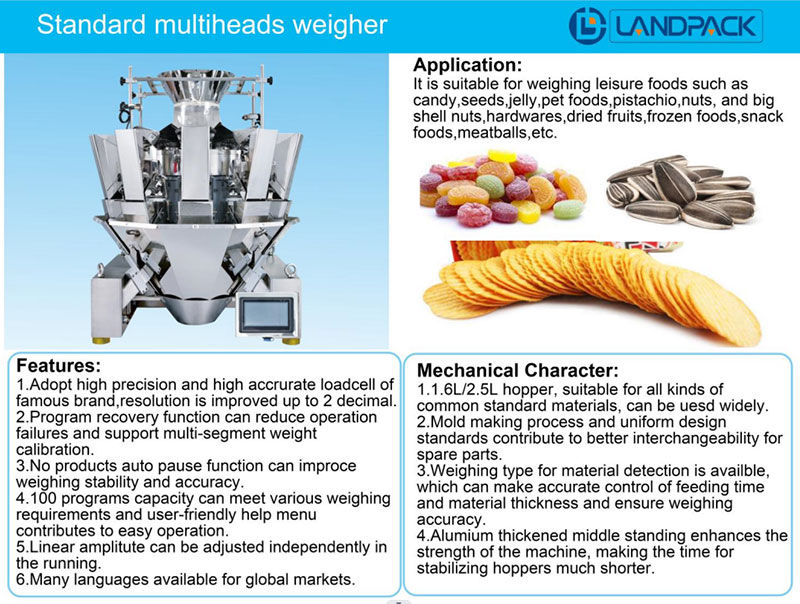

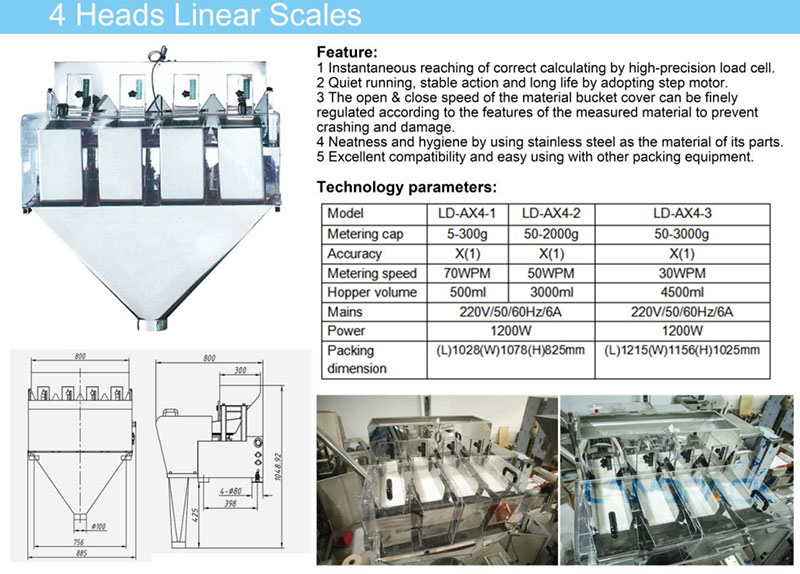

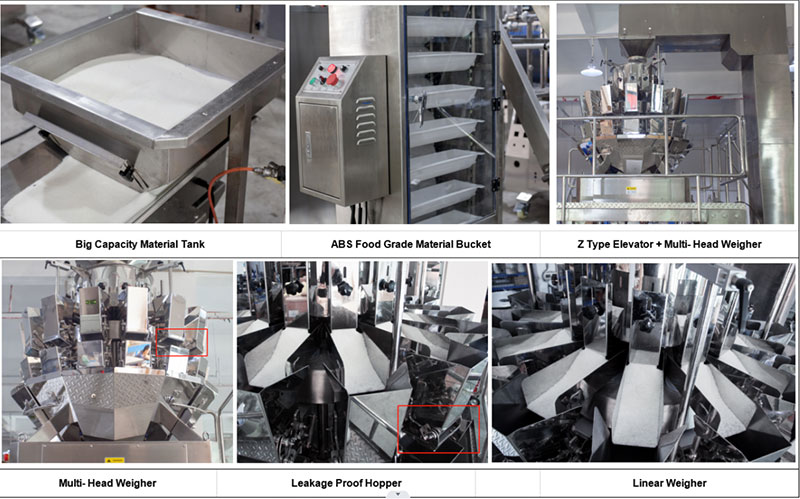

You can match with different types weigher as below

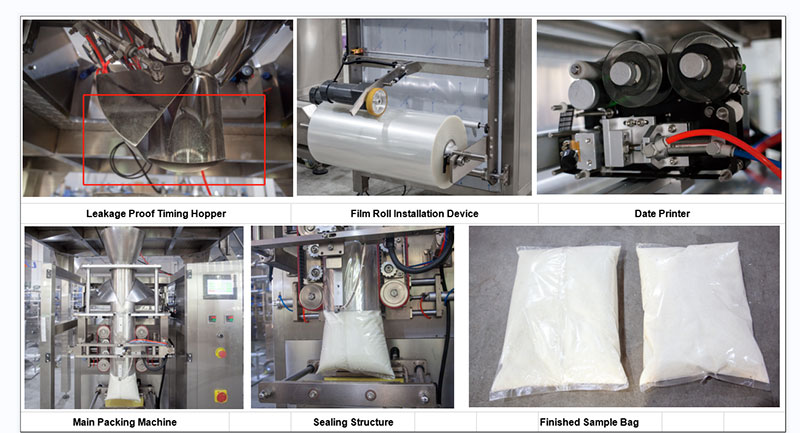

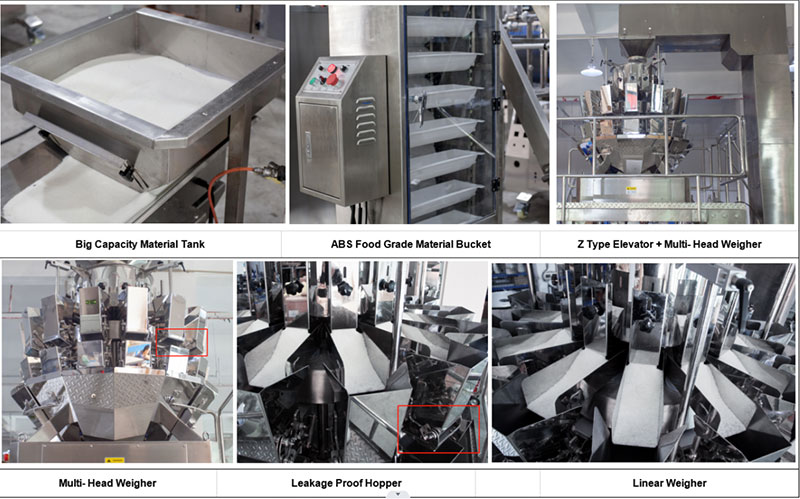

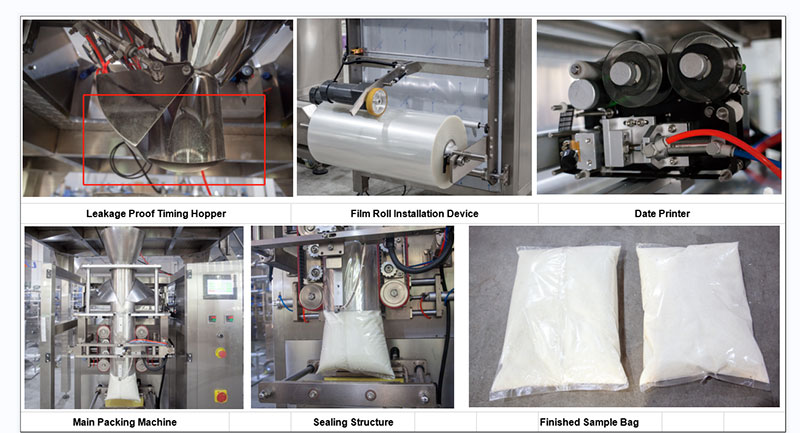

Machine details picture below

If you have some granules that need to pack by weighing, just contact us, and we will provide the best packing solution for you, all of our machines and the weighing system can customize according to your product and bag type.

Looking forward to getting your feedback!