Nails are pointed heads of hard metal (usually steel) used to hold things such as wood. Hammers drive nails into objects, and recently there are electric nail guns and gas nail guns. The reason why the nail can stabilize the object is that it hangs on it by its own deformation and relies on friction. Nails are one of the most common things in renovations. Iron-cast nails are also called iron nails, and Steel-cast nails are also called steel nails.

In engineering, carpentry, and construction, a nail refers to a pointed, hard metal (usual steel) used to hold things such as wood in place. Hammers drive nails into items. There are also electric nail guns and gas nail guns. The reason why the nail can stabilize the object is that it hangs on it by its own deformation and relies on friction.

Nails come in different shapes due to their many uses. The most common nails are called "wire nails", and other common nail names are pins, thumbtacks, or brad nails. Nails are widely used and used in many scenarios. Generally, rivets for aircraft carriers are more expensive, and ordinary nails are cheaper.

LANDPACK Packaging Machinery specializes in designing suitable packaging machinery for various products. We specialize in all kinds of packaging machinery for more than 20 years and have rich experience. And now, let me introduce a filling line for packaging nails. It consists of five machines. The work step is unpacking, filling, sealing, wrapping, and heat shrinking. His overall appearance is as follows.

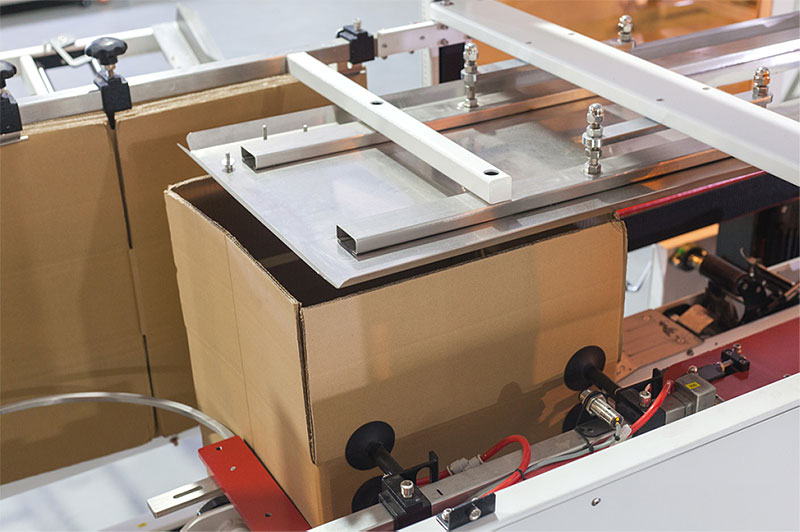

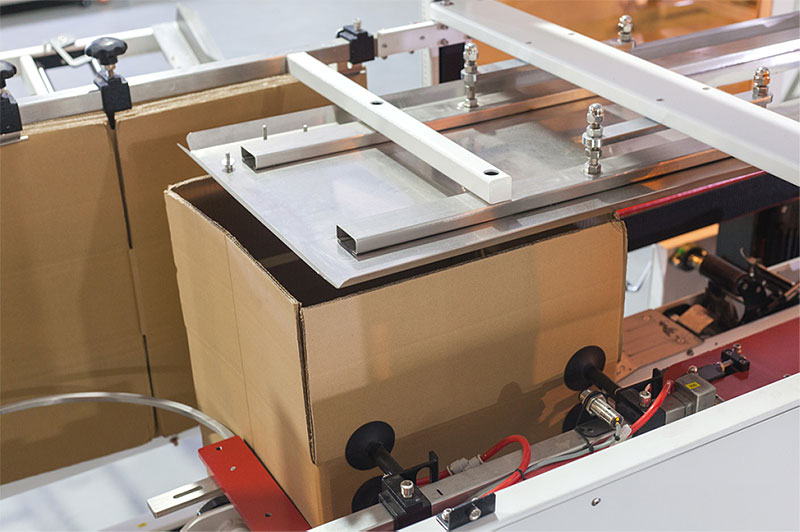

The first part is unboxing. All we need to do is to put the carton box in the right position, the machine will automatically unpack the carton box with a manipulator, and automatically seal the bottom of the box after unpacking. Only the upper opening is left for drop filling of the nails.

The second part is filling. We first lift the nails onto the 14-head scale with the skirt elevator. We can see that when the skirt elevator lifts the nails, the nails are completely exposed, which is convenient for us to observe the rise of the nails. The choice of a 14-head scale can make the measurement faster and more accurate. On the screen of the electronic scale, we can set the weight of the package and the speed of the packaging can also be seen. The operator only needs to input the weight of the package on the screen, the electronic scale will automatically combine the weighing, and drop it into the carton box after weighing.

The conveyor belt transports the nails already weighed into the carton box to the position of the case sealer. All we have to do is place the tape in the right position. When the machine is running, the carton box is automatically folded by the manipulator and then wrapped with tape.

The next step is to send the carton box into the film packing machine, similar to the previous step, all we have to do is put the film in the correct position and then run the machine. It will automatically put the film on the whole of the box. You can notice that the film is very loose at this time.

The last step is the heat shrink tunnel machine. Its main function is to stick the film tightly to the surface of the carton box, this completes the final packaging. The main purpose of this is to protect the box from damage during transportation. The film is attached to the position of the opening of the carton box on both sides, and the carton box is sealed more tightly.

The overall effect is as follows.