Easy to operate,adopt advanced PLC from Japan Mitsubishi, mate with touch screen and electric control system, the man-machine interface is friendly.

Automatic checking: no pouch or pouch open error, no fill, no seal. the bag can be used again, avoid wasting packing materials and raw materials.

Safety device: Machine stop at abnormal air pressure, heater disconnection alarm

The width of the bags could be adjusted by electrical motor.

It matches with the glass safety door. The machine will stop working when you open the door. So that it could protect the safety of operators. At the same time, it could prevent dust.

The packing materials loss low, what this machine is used the preformed bag, the bag pattern is perfect and has a high quality of the sealing part, this improved the product specification

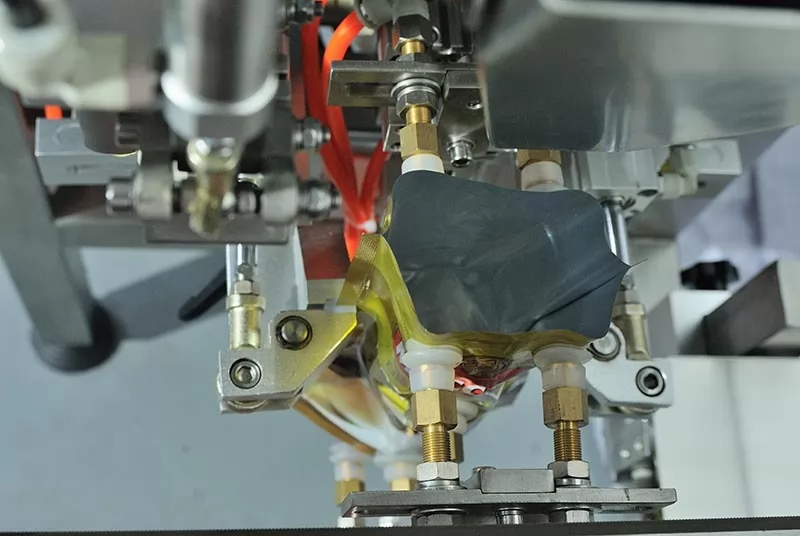

With different feeders changed to pack solid, liquid, thick liquid ,powder and so on

The packing bag suits in extensive range, suit for multi-layer compound, monolayer PE , PP and so on Preformed bag made by film and paper.